When choosing aluminium windows and doors for your dream home or new architectural project, the finish matters as much as the frame. One of the most popular and reliable finishing techniques today is powder coating, and it’s more than just a pretty colour.

Powder coating plays a major role in aluminium products’ durability and aesthetic appeal, whether you’re a homeowner looking to future-proof your home against harsh South African weather or an architect specifying finishes that need to stand the test of time, understanding how it works and how it can help you make smarter choices.

What Is Powder Coating?

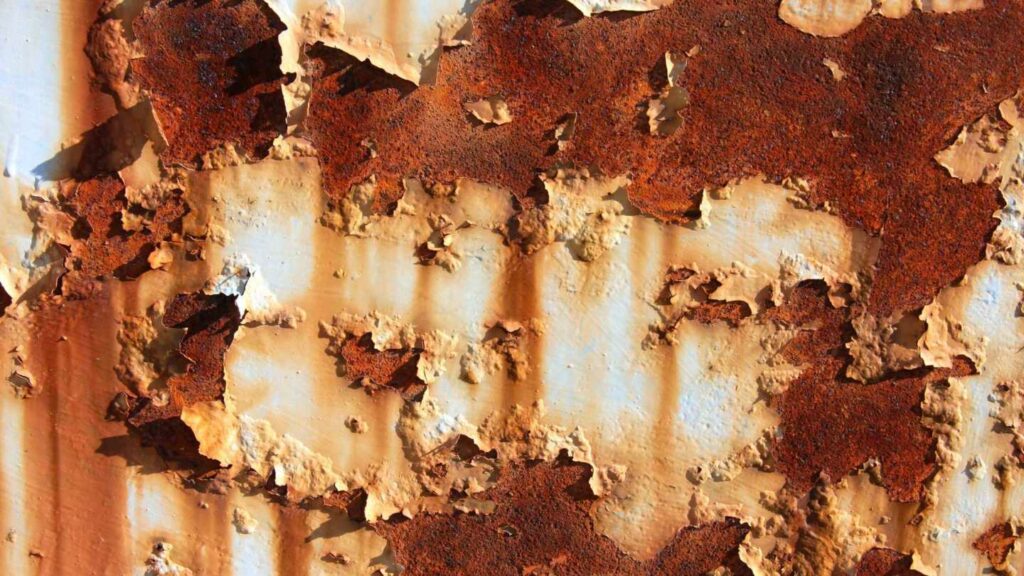

At its core, powder coating is a dry finishing process where a fine powder is electrostatically applied to a surface, usually metal, and then cured under heat to form a hard, durable layer. It’s a preferred method in the aluminium window and door industry because it offers excellent protection against corrosion, UV damage, and wear.

Why Powder Coating Is Ideal for Aluminium Windows and Doors

Aluminium is naturally corrosion-resistant, but when paired with a high-quality powder coating finish, it becomes nearly unstoppable. The result is a strong, long-lasting frame that maintains its colour, doesn’t chip or peel, and needs almost no maintenance.

Here’s why it has become the go-to for South African window and door finishes:

- Weather Resistance: It can withstand heat, humidity, and coastal air.

- Eco-Friendly: No harmful solvents are used, and any overspray can be recycled.

- Wide Colour Range: Customisable to match modern home designs.

- Low Maintenance: Just a quick wash now and then.

Powder Coating: Step-by-Step Process

Let’s break down the powder coating procedure so you can see what goes into making Fenster’s premium finishes so reliable.

1. Surface Preparation

Before anything else, the aluminium must be cleaned and treated. This step is critical. Any dirt, oil, or oxidation left on the surface can prevent the powder from adhering properly.

- Aluminium is usually degreased and etched.

A chemical pre-treatment is applied to improve adhesion and corrosion resistance.

2. Powder Application

Once the surface is prepped and dried, the powder coating is applied using an electrostatic spray gun. The charged powder particles cling to the aluminium surface, ensuring even coverage.

3. Curing

After application, the coated aluminium is placed in an oven where it’s baked at temperatures around 180–200°C. This melts the powder, creating a uniform and durable finish.

4. Cooling and Inspection

Once cured, the aluminium is cooled naturally before being inspected for any imperfections. Only then is it ready for fabrication or installation.

Common Types of Powder Coating Finishes

Here’s a quick comparison of different powder coating finishes you might encounter when specifying windows and doors:

Finish Type | Texture | Best For | Notes |

Matte | Smooth, low sheen | Modern, minimalist homes | Hides fingerprints well |

Gloss | Shiny, reflective | Bold architectural statements | Shows dust more easily |

Textured | Slightly rough feel | High-traffic or commercial spaces | Hides scratches and imperfections |

The Value of Quality Powder Coating in Construction

It’s easy to overlook the coating when choosing your windows and doors, but the finish is what protects your investment long-term. For homeowners, this means less time on upkeep and more time enjoying their home. For architects, it ensures your projects retain their design integrity for years to come.

At Fenster, every aluminium window and door we produce goes through a meticulous powder coating process using top-tier materials. We’re not just ticking a box, we’re setting a standard.

Let Fenster Add the Finishing Touch

Choosing Fenster means choosing a quality partner. From corrosion resistance to colour consistency, our powder coating process ensures your windows and doors look beautiful and perform brilliantly for years.

Explore our full range of aluminium products, request a sample, or chat with our expert team to see how we can help bring your next project to life, with a finish that lasts.